How Much Do Construction Workers Make? Surprising Stats in 2025

0 Comments

/

In today's bustling construction industry, one question often…

Basement Finishing: Turning Unused Space into Valuable Living Areas

Unlocking Your Home’s Hidden Potential with Basement Finishing

Basement…

https://jrayconstruction.com/wp-content/uploads/2024/08/pexels-tiger-lily-4484042_35.webp

1213

1820

Michael William

https://jrayconstruction.com/wp-content/uploads/2020/02/logo.jpg

Michael William2024-08-05 06:24:482025-05-05 05:54:50Benefits of using sustainable materials in construction

https://jrayconstruction.com/wp-content/uploads/2024/08/pexels-tiger-lily-4484042_35.webp

1213

1820

Michael William

https://jrayconstruction.com/wp-content/uploads/2020/02/logo.jpg

Michael William2024-08-05 06:24:482025-05-05 05:54:50Benefits of using sustainable materials in construction

Commercial & Residential Construction Services in Irvine - Guide

Irvine, California, known for its planned urban development and…

Residential Construction Services in Irvine

Irvine, California, is a city known for its beautiful homes and…

Residential Construction Services in Irvine

Irvine, a city in California, is known for its beautiful homes…

How To Calculate Price Per Square Foot New House Construction?

New house construction is a major undertaking. You need to be…

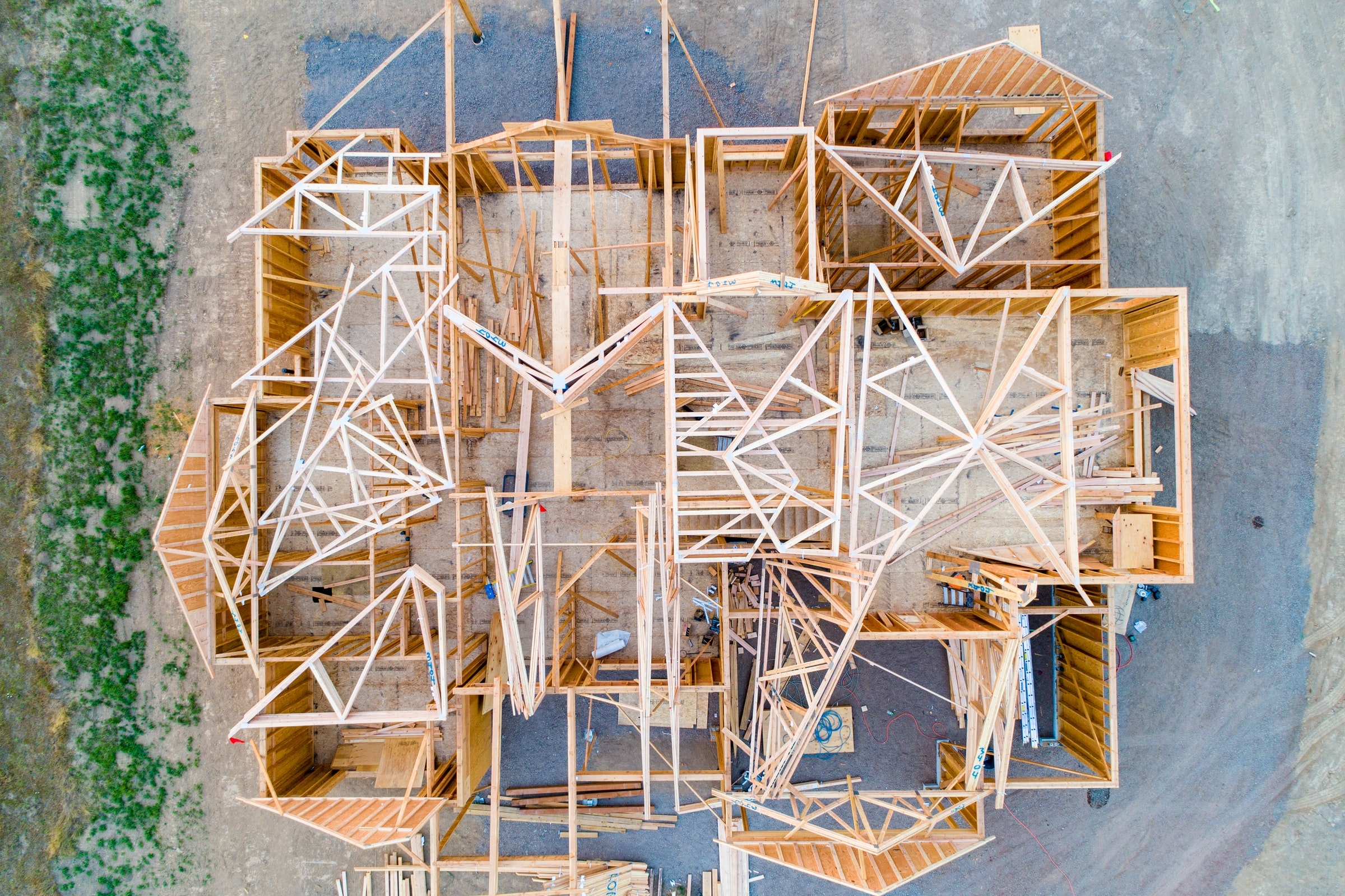

What Is Balloon Frame Construction?

The Balloon frame was a popular form of timber structure used…

What Is Post Frame Construction?

Post Frame Construction is a wooden frame system fabricated with…